How to test the Quality of Fly Ash Bricks

As we’re heading towards sustainable construction practices, Harden Bricks is contributing to the rise of fly ash bricks in Kolkata. Fly ash brick blocks are light in weight in comparison to its alternatives and the quality makes them more suitable for multi-story buildings. But the question is how to test the quality of Fly Ash Bricks?

We’ve compiled the three testing procedures for fly ash bricks. Here is how to test the quality of fly ash bricks.

The testing procedure for fly ash bricks

The three major tests that should be undertaken at the site are compressive strength test, water absorption test, and efflorescence test. The procedure is well described below:

(a) Compressive Strength Test:

-

- Apparatus – A compression testing machine (having capacity preferably 500 kN/50 Tons or above) and duly calibrated at intervals of every 3 (three) months.

- Preconditioning of sample – Remove any unevenness observed in the bed faces to provide two smooth and parallel faces. If required, a grinder may be used for the same. Immerse in the water at room temperature for 24 hours. Remove the specimen and drain out any surplus moisture by leaving the specimen at room temperature for 3-4 minutes. Fill the frog (where provided) and all voids in the bed face flush with cement (1 part of cement; 2 parts of clean coarse of grade 3 mm and down). Store under damp jute bags for 24 hours followed by immersion in clean water for 3 days. Remove and wipe out traces of excess water prior to starting the test. However, in cases where immediate indicative test result is required to allow unloading of bricks at the site, the procedure of filling the ‘brick frog’ with cement mortar is substituted by placing sand and uniformly screeding the same to fill up the void. Excess sand particles are brushed away from the face of the brick to avoid ‘point load’ during testing.

- Testing Process – Place the specimen with flat faces horizontal and mortar/sand filled face facing upwards between two 3-ply plywood sheets each of 3 mm thickness and carefully centered between plates of the testing machine. Apply load axially at a uniform rate of 14N/mm2 (140 kgf/cm2) per minute till failure occurs and note the maximum load at failure. The load at failure shall be the maximum load at which the specimen fails to produce any further increase in the indicator reading on the testing machine.

- Report – The report shall be prepared as per the calculation method given below:

Compressive Strength in N/mm2 (kgf/cm2) = Maximum Load at failure in N (kgf) [divided by] Average area of the bed faces in mm2 (cm2)

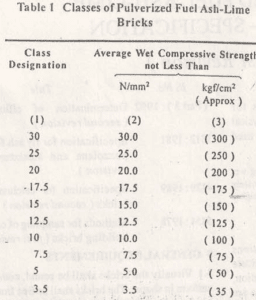

Classes of Fly Ash Bricks approved by Bureau of Indian Standards [as per IS: 12894 – 2002]

(b) Water Absorption Test:

- Apparatus – A sensitive balance capable of weighing within 0.1 percent of the mass of the specimen and ventilated oven along with accessories for handling hot material.

- Preconditioning of sample – Dry the specimen in a ventilated oven at a temperature of 1050C to 1150C till it attains substantially constant mass. Cool the specimen to room temperature and obtain its weight (M1). Specimen warm to touch shall not be used for the purpose.

- Testing Process – Immerse completely dried specimen in clean water at a temperature of 270C (+/-) 20C for 24 hours. Remove the specimen and wipe out any traces of water with a damp cloth and weigh the specimen. Complete the weighing 3 minutes after the specimen has been removed from water (M2).

- Report – The report on water absorption, percent by mass, after 24-hour immersion in cold water shall be calculated in the method given below:

{M2-M1 [divided by] M1 } [multiplied by] 100

(c) Efflorescence Test:

- Apparatus – A shallow, flat bottomed dish containing sufficient distilled water to completely saturate the specimens. The dish shall be made of glass, porcelain or glazed stoneware of size 180 mm x 180 mm x 40 mm depth (for square-shaped) and 200 mm dia x 40 mm depth (for cylindrical shaped).

- Testing Process – Place the end of the bricks in the dish, the depth of immersion in water being 25 mm. Place the whole arrangement in a warm (i.e. 200C to 300C) well-ventilated room until all the water in the dish is absorbed by the specimens and the surplus water evaporates. Cover the dish containing brick with a glass cylinder, so that excessive evaporation from the dish may not occur. When the water has been absorbed and bricks appear to be dry, place a similar quantity of water in the dish and allow it to evaporate as before. Examine the bricks for efflorescence after the second evaporation and report the results.

- Report – The liability to efflorescence shall be reported as “nil”, “slight”, “moderate”, “heavy” or “serious” in accordance with the following definitions:

- NIL – When there is no perceptible deposit of efflorescence.

- SLIGHT – When not more than 10% of the exposed area of the brick is covered with a thin deposit of salts.

- MODERATE – When there is a heavier deposit than under ‘slight’ and covering up to 50% of the exposed area of the brick surface, but unaccompanied by powdering or flaking of the surface.

- HEAVY – When there is a heavy deposit of salts covering 50% or more of the exposed area of the brick surface, but unaccompanied by powdering or flaking of the surface.

- SERIOUS – When there is a heavy deposit of salts accompanied by powdering and/or flaking of the exposed surface.

Fly ash bricks are environment-friendly, more affordable and contribute to a greener future. Harden Bricks is one of the finest fly ash manufacturers in Kolkata. For more information, email us at – info@hardenbricks.com or simply visit our website – www.hardenbricks.in

Leave a comment